HOW IS CROSS CONTAMINATION IN HEALTHCARE ENVIRONMENTS?

One of the main aspects to be considered in the health safety of hospital environments is cross contamination. As all the various professionals who deal with hospital sanitization or RSA are well aware, this phenomenon occurs when pathogens are transferred from one environment to another, frustrating the operators' efforts to contain them.

It is precisely by analyzing in detail the different operational aspects of cleaning and sanitization, that in Taxon we thought of the new UniQo trolley line, to solve one by one and definitively, the different flaws of the current working methods. Ensuring hygienically safe and healthy environments, making cross-contamination impossible during sanitation operations was the starting point.

Use of clean fringes for each individual environment

In the operation of sanitization of environments with high pathogenic risk, such as hospitals, health facilities and RSA, the safest way carried out by the staff of cleaning companies is to use a single flat mop for each individual environment. This methodology is designed to prevent potentially pathogenic agents from being transported from one environment to another.

Unfortunately, the trolleys equipped with a wringer and two buckets, to contain one the cleaning liquids, the other the dirty water, do not prevent to dip a second time the fringe or mop in the first bucket, thus nullifying the precautions to prevent cross-contamination.

The traditional impregnation process

With the traditional system it is not possible for the operator to evaluate the amount of liquid that will impregnate the flat mop, so in the case of larger environments a second impregnation of the flat mop may be necessary to complete the sanitization. Which would mean bacterial pollution of the bucket with detergent.

In the case of smaller rooms, such as bathrooms, it might be more convenient and also economical for the operator to continue cleaning with the same flat mop even in an adjacent environment, thus transporting possible pathogens from the first room to the second.

Hands as a Vehicle of Contamination

It may seem strange but the main vehicle of physical contamination is represented by the hands of the operators, both because handling the flat mop can infect them and carry pathogens on the various tools used for cleaning such as walls and furnishings of the premises.

The use of gloves, although important for the operator, requires a lot of care and the need to be changed and washed frequently, and does not guarantee that items, cleaning tools (e.g. trolley, buckets, wringer handle, etc.) and even food, are not contaminated when touched.

Colour code to prevent contamination

A widely practiced precaution is the adoption of a color code to distinguish the cloths used in different areas. It represents a further step in the prevention of cross contamination. But when used in the practice of sanitizing the floors that involves the use of the wringer, it does not solve the different problems related to the contamination of detergents impregnation fringes, as explained above.

UniQo Solution for Maximum Health Safety

Analyzing all aspects of direct and indirect cross-contamination, at Taxon we focused on how we could create a system that would not allow the contact of flat mop and potentially infected liquids with clean equipment, ready for use.

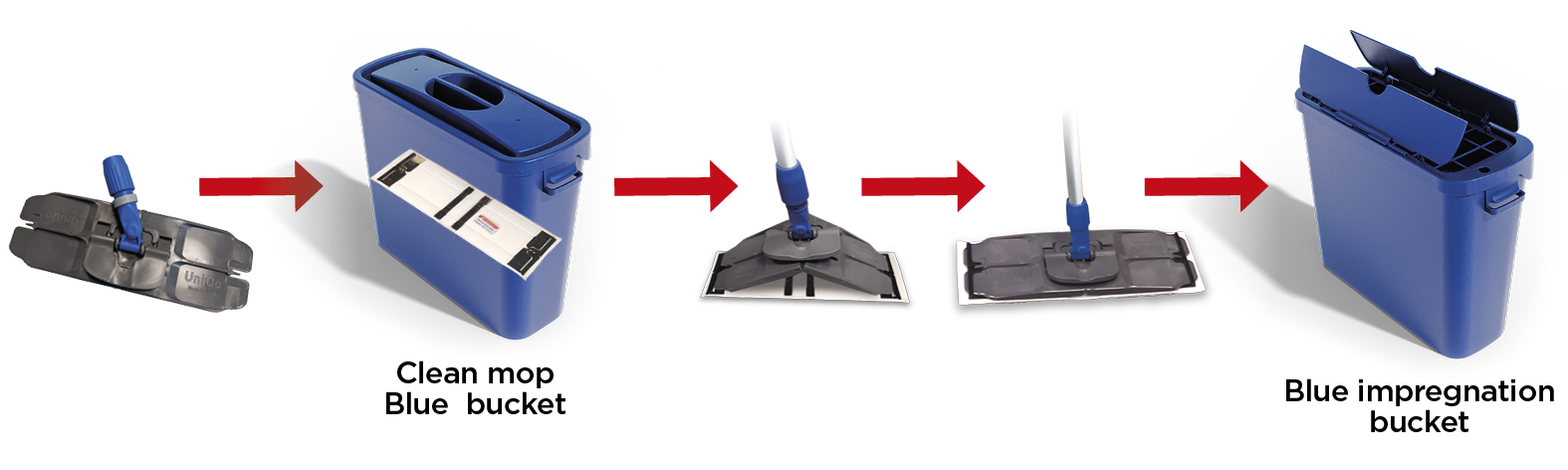

We flat mop therefore redesigned the impregnation process from scratch, keeping the fringes clean and those already used always separate and making contact between them virtually impossible, as well as avoiding contact with the hands of operators. This also involved rethinking the system of releasing and attaching the flat mop, which could not involve direct manipulation by operators.

This is how the revolutionary impregnation process of UniQo was born. Based on a frame with flat mop to hook / quick and automatic release, and 3 special and new buckets:

- the first blue bucket, contains only the clean flat mop to be impregnated

- the second blue bucket, the real heart of the system, contains the sanitizing liquids that through 12 spray nozzles impregnate the flat mop with the amount programmed according to the surface of the room to be processed. This technology has also allowed to eliminate the pre-impregnation phase (but we will talk about this in a future article)

- the third bucket, red, is dedicated to containing only the flat mop already used, eliminating the need for manual wrinkling ensures that the dirt collected can never come into contact and spread to other areas.

Thanks to this innovative process, UniQo is a real mobile washing station with on board the best technology for fully touch-impregnationfree, which allows operators to carry out all the activities without a direct contact with the hands.

Pressure Impregnation

The main strength and uniqueness of UniQo is its revolutionary process of pressing impregnation of flat mop that takes place in its special Blue bucket. Thanks to this UniQo, depending on the size of the room and the condition of the floor to be treated, it can take from 5 to 20 seconds to impregnate the flat mop, to ensure maximum health safety.

Adaptability and Safety

In conclusion, UniQo is the innovative solution that revolutionizes the way healthcare security is addressed in hospital environments. Prevents direct and indirect cross contamination with touch-free systems and the use of clean cloths for each area. UniQo is the ideal partner to ensure safe, hygienic and meeting the highest standards. In addition, its size and its complete equipment allows you to always have at hand all the tools and equipment for sanitizing operations.

Equipping your cleaning company with the new UniQo trolleys means investing in the quality of work and the health safety of your employees.

Want to see UniQo in action? Click here

UniQo still has many secrets to reveal. Go back to these pages, you will find new reasons to include UniQo among your professional cleaning equipment.

CONTACT US

Write us for more information.